Cost-Effective & Durable

Flexible & Adaptabl

Deep-Draft Berthing

Hydro-Pneumatic Fenders

Hydro-Pneumatic Fenders (Vertical Pneumatic Fenders)

Reliable protection for submerged hulls – ideal for submarines, catamarans, and semi-submersibles.

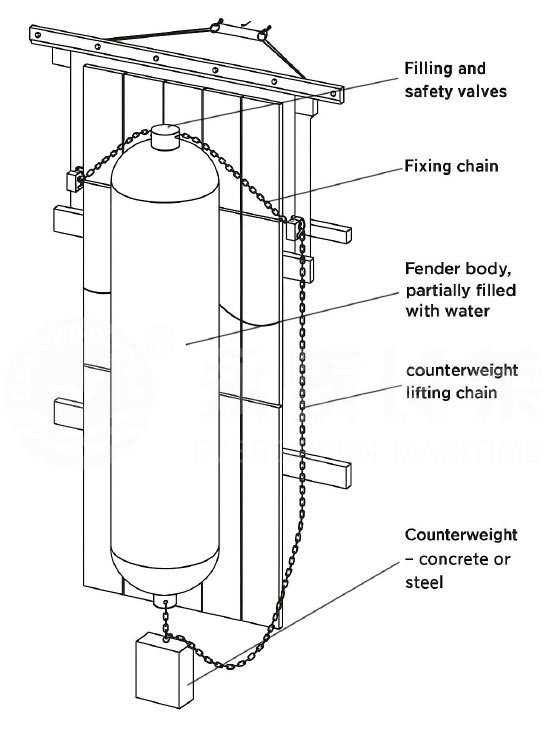

Hydro-pneumatic fenders are a specialized type of pneumatic rubber fender designed for vessels with berthing points below the waterline—such as submarines, catamarans, and semi-submersible platforms. Installed in a vertical position, these fenders are partially filled with water and air, and fitted with an internal counterweight to ensure stable vertical alignment.

This configuration ensures continuous contact and optimal protection for the submerged hull during berthing, even with tidal variations.

Key Features

of Hydro-Pneumatic Fenders (Vertical Pneumatic Fenders)

- Vertical installation with water ballast and internal counterweight

- Adjustable air-to-water ratio to suit different vessel drafts

- Stable performance unaffected by tide or wave action

- Flanged ends for easy water filling and drainage

- Built-in safety valve to release excess pressure

- Low hull pressure and minimal maintenance required

- Durable in extreme climates

Performance Specifications

Designed for high burst strength:

- ≤ 2000mm diameter: min. 4.9 kgf/cm²

- ≥ 2500mm diameter: min. 5.7 kgf/cm²

Advantages

- Cost-effective solution for deep-draft vessel berthing

- Easy to relocate or transport for emergency berthing setups

- Low installation and maintenance costs

- Self-adjusting to tidal variations

- Long service life with minimal upkeep

Performance of Hydro-Pneumatic Fenders

| Fender size [mm] | without water 60 % deflection | filled with water 45 % deflection | |||

| Energy [kJm] | Reaction [kN] | Ratio water / Air [N] | Energy [kJm] | Reaction [kN] | |

| 1,700 x 7,200 | 560 | 1,810 | 65 / 35 | 134 | 611 |

| 2,000 x 6,000 | 647 | 1,766 | 65 / 35 | 155 | 599 |

| 2,500 x 5,500 | 928 | 2,037 | 65 / 35 | 223 | 687 |

| 3,300 x 6,500 | 1,911 | 3,169 | 60 / 40 | 616 | 1247 |

| 3,300 x 10,600 | 3,120 | 5,170 | 55 / 45 | 589 | 1275 |

Installation Instructions for Hydro-Pneumatic Fenders

Hydro-pneumatic fenders must be installed vertically to ensure effective protection of submerged hull structures. The installation process typically involves the following steps:

- Positioning and Suspension

The fender is suspended vertically in the water using chains, shackles, or wire ropes, connected to a fixed support structure such as a quay wall or floating dock. A counterweight inside the fender helps maintain vertical stability during operation. - Filling with Water and Air

Use the flanged openings at each end to fill the fender with the required volume of water and compressed air. The air-to-water ratio should be set according to the vessel’s draft and operational requirements. Standard filling guidelines are typically provided by the manufacturer. - Pressure Adjustment and Safety Check

Adjust internal air pressure using a compressor and verify using a pressure gauge. Ensure the safety valve is functional to prevent over-inflation during compression. The target pressure should comply with the fender’s specification (e.g. 4.9 or 5.7 kgf/cm² depending on size). - Final Inspection

Check all connection points, fittings, and the fender’s orientation to confirm secure installation. Conduct a brief test berthing, if possible, to ensure performance and clearance are as expected.

EVERGREEN Hydro-Pneumatic Fenders

Smart Berthing Solution for Submarines and Deep-Draft Vessels

Designed and engineered by EVERGREEN, our hydro-pneumatic fenders ensure reliable, vertical protection for submerged hulls. With a water-air system and robust counterweight design, they offer superior performance, easy installation, and long-term durability in even the most demanding marine environments.