High energy absorption

Zero maintenance

All-weather berthing protection

Evergreen Foam-Filled Fender

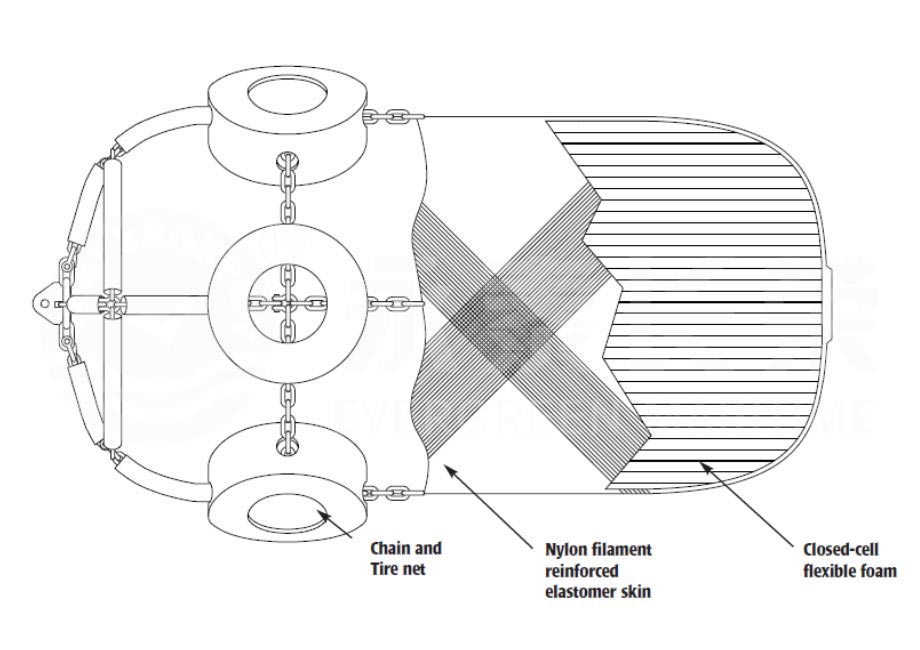

Qingdao Evergreen’s foam-filled fenders are primarily composed of a closed-cell elastic foam core, reinforced nylon cord layers, and a durable outer skin. The reinforced nylon layers are wrapped around the internal flanges at both ends of the fender. A steel rod or heavy-duty chain runs through the foam core and connects the two end flanges, integrating all components into a solid, high-strength structure with excellent resistance to pulling, compression, and impact forces.

The energy-absorbing foam core typically uses polyethylene foam or EVA with a broad compression plateau, allowing it to absorb impact energy efficiently.

The outer protective layer is available in polyurethane or rubber.

Rubber-skin foam fenders offer superior resistance to shearing and tearing, making them ideal for demanding berthing conditions.

Qingdao Evergreen foam-filled fenders are truly customizable fenders designed and manufactured to meet specific needs.

From the energy-absorbing foam core to the protective outer skin, every component can be optimized according to customer requirements, achieving the best balance between performance and cost.

Advantages

- High energy absorption, low reaction force

- Wide tolerance for berthing angles and impact directions

- Unsinkable structure

- Maintenance-free

- High operational safety

Types of Evergreen Foam Filled Fenders and Their Applications

Netless Foam Fender

Features: Simple, clean design without an outer net. Smooth polyurethane skin, lightweight, and easy to handle.

Applications: Suitable for yachts, passenger ships, and commercial vessels where a non-marking surface and low maintenance are important.

Foam Fender with Chain Tire Net

Features: Heavy-duty chain and tire net provides extra protection against abrasion and damage. Extremely durable for rough conditions.

Applications: Widely used for oil tankers, container vessels, and ship-to-ship (STS) transfers where strong impact resistance is required.

Features: Designed to float around a fixed monopile, rotating with the vessel’s movement to reduce shear forces. Long service life with minimal maintenance.

Applications: Ideal for bridge protection, offshore terminals, and areas with strong tidal currents where vessels need to stay aligned around fixed structures.

Structure and Materials

The closed-cell, cross-linked polyethylene foam core is fabricated as a single, homogeneous body. This resilient construction ensures the fender remains unsinkable while providing high energy absorption with relatively low reaction force compared to other fendering systems.

The outer skin is constructed of a urethane elastomer or rubber, reinforced with continuous nylon filament winding. Multiple layers are applied to increase overall strength, with special reinforcements at both ends to withstand peak stress areas. This layered structure significantly enhances resistance to deformation and shearing forces.

A heavy-duty internal chain or steel bar (optional based on customer requirements) runs through the fender to transmit tensile loads, ensuring structural integrity during high-stress operations.

Integral swivel end fittings, made of high-quality steel, offer secure attachment points that remain unobstructed even when the fender is compressed.

Standard performance foam fenders

Qingdao Evergreen offers foam fenders with low, medium, and high reaction forces, as well as polyurea or rubber outer skins, tailored to meet customers’ specific berthing requirements.

| Diameter x Length | Standard Capacity Foam Filled Fenders | ||||

| Metric | English | Energy Absorption | Reaction Force | ||

| at 60% Compression | at 60% Compression | ||||

| (mm) | (ft) | (ft-kips) | (ton-m) | (kip) | (ton) |

| 1000×1500 | 3.3×4.9 | 35 | 5 | 39 | 17 |

| 1350×2500 | 4.4×8.2 | 112 | 16 | 94 | 42 |

| 2000×3500 | 6.5×11.5 | 335 | 47 | 190 | 86 |

| 2500×4000 | 8.2×13.1 | 591 | 82 | 269 | 122 |

| 3300×4500 | 10.8×14.7 | 1105 | 153 | 380 | 172 |

| 3300×6500 | 10.8×21.4 | 1786 | 248 | 614 | 279 |

Full-size foam fender performance data is available on request.

Polyurethane-Skin Foam Fenders

Advantages:

- Excellent Abrasion Resistance: Polyurea coatings are highly resistant to wear, making them ideal for high-traffic berthing areas.

- Superior Weather and UV Resistance: Excellent durability in marine environments, including resistance to seawater, chemicals, and sunlight.

- Lightweight: The coating is thin and adds minimal weight, making installation and handling easier.

- Smooth Surface: Reduces friction against hulls and is easy to clean and maintain. Offers a sleek, modern appearance.

Disadvantages:

- More Difficult to Repair: Requires specialized tools and materials for surface repairs.

- Less Flexible in Extreme Cold: Slightly reduced flexibility in very low-temperature environments.

Rubber-Skin Foam Fenders

Advantages:

- Good Impact Absorption: Rubber has excellent elasticity and shock absorption properties.

- Proven and Cost-Effective: A traditional, widely used material with mature processing techniques.

- Flexible in Cold Weather: Maintains flexibility and performance in low temperatures.

- Easy to repair, on-site maintenance possible

Disadvantages:

- Higher Surface Friction: May cause scuffing or damage to vessel hulls during contact.

- Heavier: Generally heavier than polyurea-coated fenders, requiring stronger support structures.

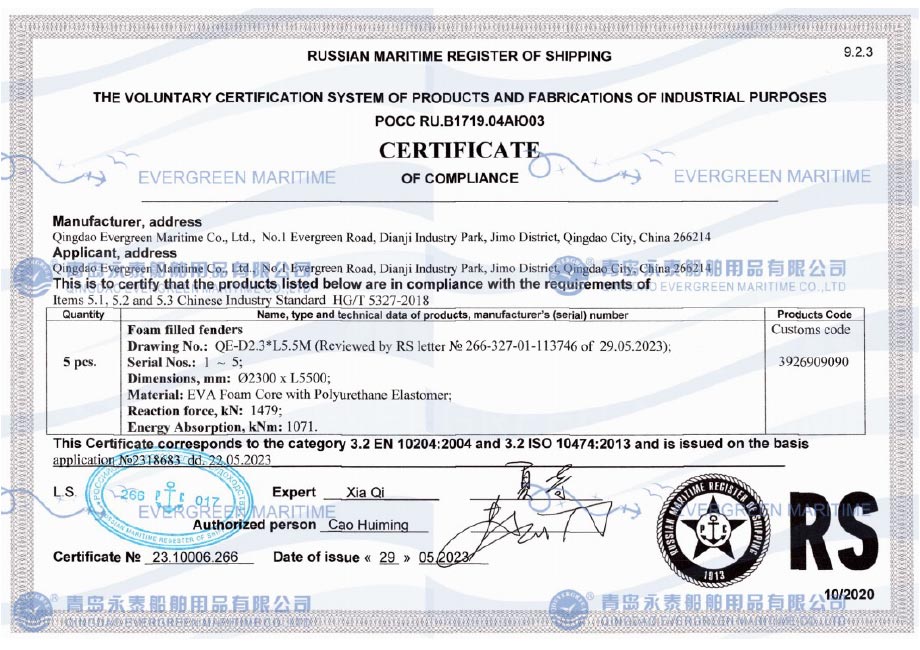

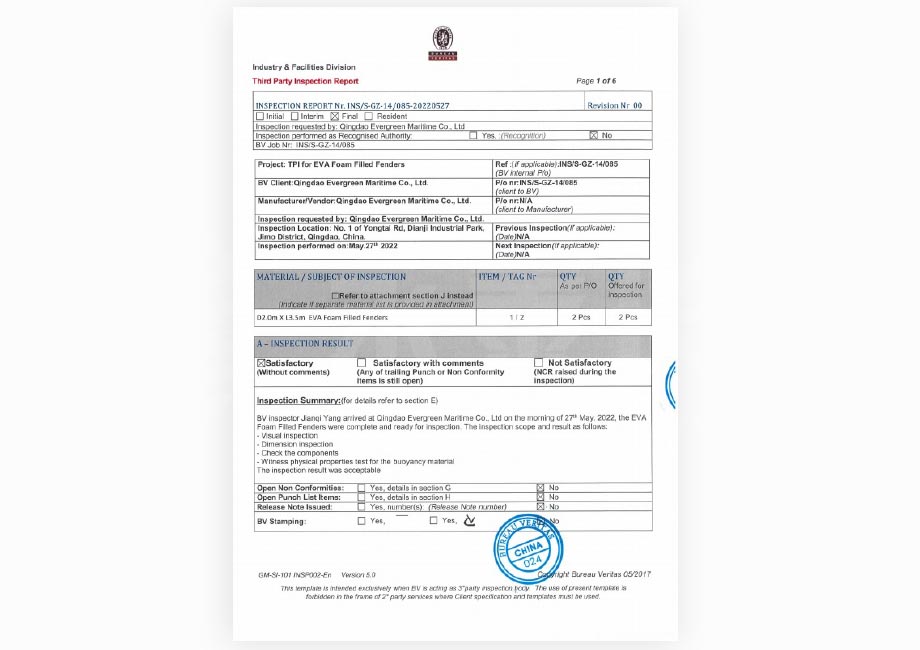

Standards and Certificates for Evergreen Foam Filled Fenders

Evergreen Foam Filled Fenders comply with PIANC and OCIMF Guidelines, meet naval standards, and are certified by leading classification societies — ensuring global trust and proven reliability.

Drilling Test of Evergreen foam fenders

Compression Test of Evergreen donut foam fenders

BV certificate of Evergreen foam fenders