Safety Factor > 5.0

ISO 14409 Certified

Superior Performance

Extended Service Life

Marine Airbag History

Product Overview

Marine airbag also called pneumatic roller, was invented and developed in China, designed for launching vessels in a safe, efficient, and economical way. A launching airbag consists of a cylindrical body with two conical heads, constructed with multiple layers of rubber and synthetic-tire-cord fabric. When inflated with compressed air, the airbags can lift and roll vessels ranging from thousands to tens of thousands of tons.

Technological Evolution

The first-generation marine airbags (1980s) used canvas-reinforced rubber layers and were limited to vessels under a few hundred tons due to low working pressure. With the advancement of materials and manufacturing technology, modern airbags now use high-strength nylon cord fabric combined with butyl rubber for superior air-tightness and pressure performance.

Applications & Achievements

As China’s shipbuilding industry has expanded, airbag launching has been widely adopted for large vessels, including those over 10,000 tons in light weight. Qingdao Evergreen has been a leading innovator in this field and holds the world record for launching the heaviest vessel using airbags — 24,800 tons on self-weight.

Standards

Evergreen marine airbags comply with the following standards:

- ISO 14409:2011 Ships and marine technology — Ship launching airbags

- ISO 17682:2013 Ships and marine technology — Methodology for ship launching utilizing airbags

- GBT 33487-2017, China National Standard

Product Highlights

Safety Coefficient > 5.0

Premium materials and patented technology give Evergreen airbags a safety coefficient over 5.0, ensuring safety even in demanding operations.

ISO 14409 Certified

Evergreen launching airbags meet all ISO 14409 standards and can be certified by all major IACS classification societies.

Superior Performance

Our airbags operate at higher working pressure, offering greater lifting force and safety margin.

Extended Service Life

Special exterior coating design improves resistance to puncture, abrasion, and aging. Average service life exceeds 6 years.

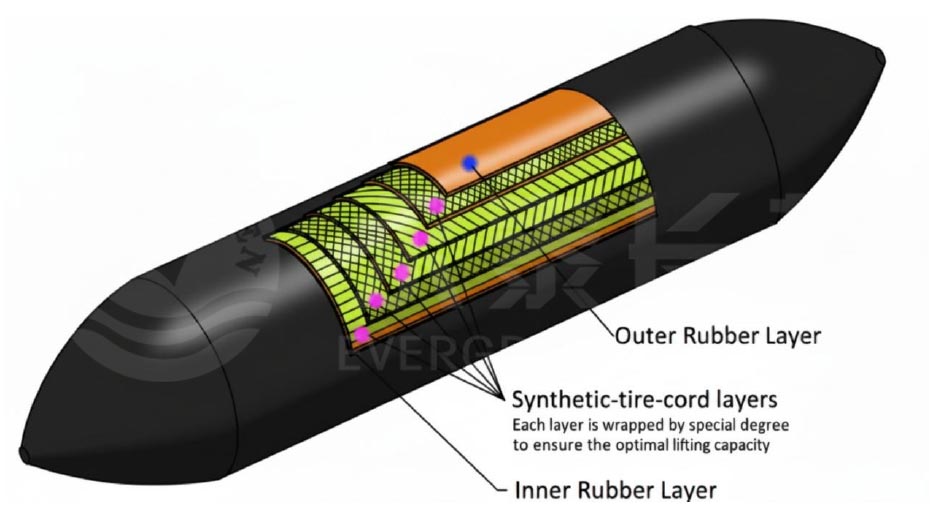

Outer Rubber Layer

The outermost layer protects the internal components and resists puncture, abrasion, and aging. It consists of high-tensile synthetic mesh fabric and rubber. Depending on application needs, the outer layer can be customized to ensure peak performance under different working conditions.

Reinforcement Layer (Synthetic Tire Cord)

This layer determines the airbag’s strength and durability. Evergreen uses premium nylon-66 tire cord with superior elasticity and bending resistance. Optimized winding angles and layering ensure maximum safety and performance.

Inner Air-Tight Layer

Made from high-quality butyl rubber, this inner layer ensures excellent air tightness under high pressure.

End Fittings

One end of the airbag is equipped with an inflation valve, and the other with a lifting ring. End fittings are available in stainless steel or hot-dip galvanized steel.

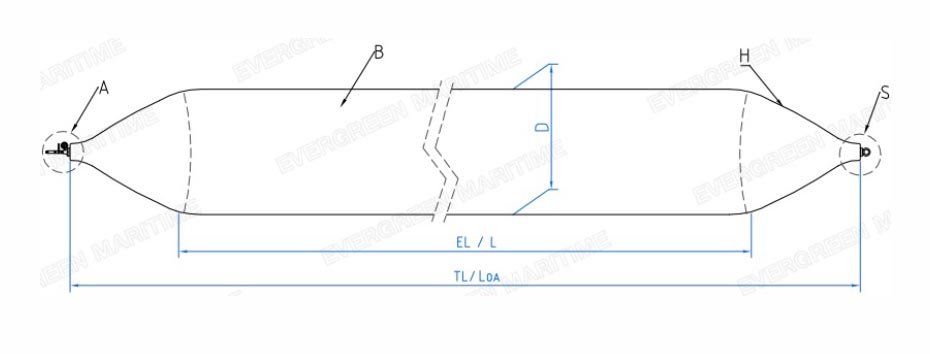

Product Specifications

Evergreen marine airbags Product Specifications

Available sizes:

Diameter (D): 0.5 m – 3.5 m

Effective Length (EL): 4 m – 40 m

Reinforcement Layers: 4 – 12 layers

Custom sizes available on request.

Three Airbag Categories

Classification & Commonalitie

Marine airbags can be classified into three categories based on their applications: ship launching airbags, ship drydocking airbags, and marine salvage airbags. While these airbags share a similar basic structure, they differ in specific functions.

Launching vs. Hauling Airbags

For example, the main distinction between ship launching airbags and hauling airbags lies in the outer layer design: ship launching airbags require a low-friction exterior for smooth launching, whereas ship hauling airbags need a tough outer skin to prevent punctures or cuts during ship hauling operations.

Unique Salvage Airbag Design

Marine salvage airbags rely primarily on buoyancy and are designed to be lighter in weight and more airtight compared to ship launching and hauling airbags.

Quality Control – Marine Airbags

At Qingdao Evergreen Maritime, quality is at the core of our manufacturing process. All marine airbags are tested rigorously in accordance with ISO 14409:2011 to ensure their safety, reliability, and performance.

Comprehensive Testing Procedures

To guarantee product excellence, airbags randomly selected from each batch undergo the following tests:

1. Gastightness Test

Each airbag is inflated to its rated working pressure and held for 1 hour. The internal pressure must remain stable, with a pressure drop of no more than 5%, ensuring airtight performance.

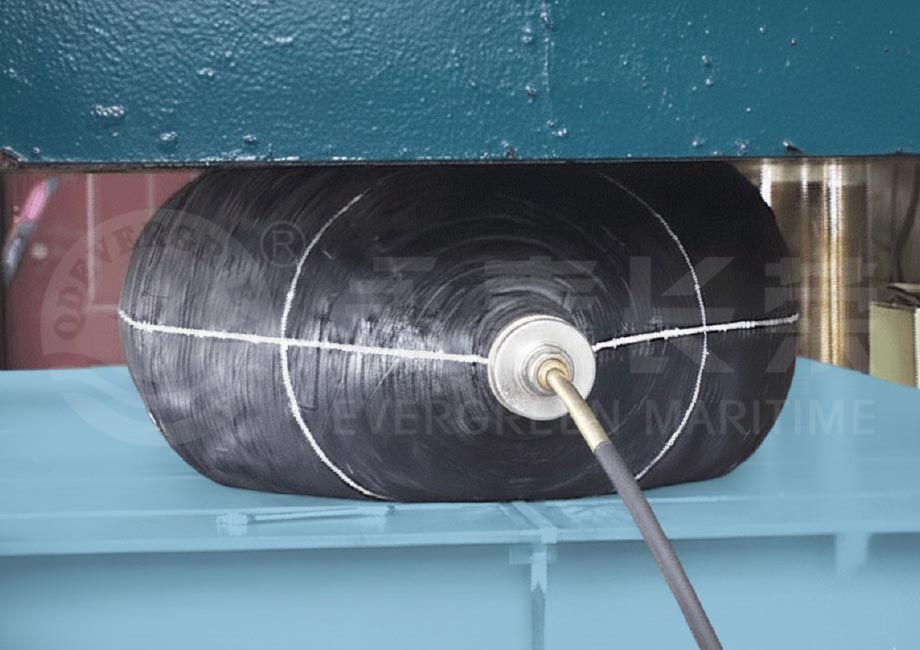

2. Bearing Capacity Test

Compression test of Evergreen marine airbag

How the bearing capacity test of Evergreen marine airbag is carried out

The load-bearing capability of the airbag is verified by applying pressure until 70% compression is reached. It must support the required load per meter of length. The airbag is further tested at 125% of the rated pressure to ensure safety under overload conditions.

3. Hydrostatic Burst Test

Filled with water, the airbag is pressurized until failure. The bursting pressure must meet or exceed the minimum value specified by ISO standards to confirm maximum strength.Hydrostatic burst testing is the most direct and effective way to assess the performance and safety of marine airbags.

Remote monitoring of airbag hydrostatic burst test

Site for airbag hydrostatic burst test

Final Product Acceptance

Before delivery, every airbag is individually inspected and tested for:

- Appearance: Smooth surface, free of cracks or defects

- Size Accuracy: Diameter and length within ±3% tolerance

Qingdao Evergreen Maritime is committed to delivering airbags that meet the highest international standards. Our strict quality control procedures ensure that every airbag we produce is safe, dependable, and built to perform under pressure.

Maintenance & Repair of Marine Airbags

At Qingdao Evergreen Maritime, we emphasize not only the reliable performance of our marine airbags but also the importance of proper maintenance and repair to extend their service life and ensure safe operation.

Marine airbags—also known as ship launching or docking airbags—are made of reinforced rubber and synthetic cord layers. They are built for durability and typically offer more than 6 years of service. However, like any rubber-based product, they require proper care and may occasionally need repair due to accidental punctures from sharp objects like steel or stones.

Maintenance & Repair of Marine Airbags

To maximize performance and longevity, marine airbags should be regularly maintained as follows:

1. Cleaning and Surface Protection

After each use, clean the airbag thoroughly with fresh water to remove dirt, salt, and residues. Then, dry the airbag completely and apply a light coating of French chalk (hydrated magnesium silicate) powder. This prevents surface sticking and rubber degradation.

2. Proper Storag

When not in use, marine airbags should be:

· Stored in a cool, dry, and sheltered environment

· Kept away from direct sunlight

· Protected from chemicals, acids, alkalis, gasoline, solvents, or oil-based substances

Avoid storing the airbags under tension or pressure, and ensure they are not folded sharply or stacked under heavy loads.

What to Do If a Marine Airbag Is Punctured

Punctures may occur during operations. Fortunately, marine airbags can be repaired, and a properly executed repair can restore the airbag to full working condition.

Grind the area of the airbag to be repaired

Apply patches to damaged area of airbags

Tips:

· Different brands of airbags may use slightly different rubber or cord compositions. Always test vulcanization time beforehand for optimal results.

· Ambient temperature can also influence curing time.

Comprehensive After-Sales Service

Qingdao Evergreen Maritime provides both online and on-site services, including airbag selection, engineering consultation, on-site repair, and technical support, ensuring safe and worry-free use of our products.