Durable Outer Skin Design

Anti-Twisting Design

Safe and Hassle-Free Operation

Character of Evergreen ship drydocking airbags

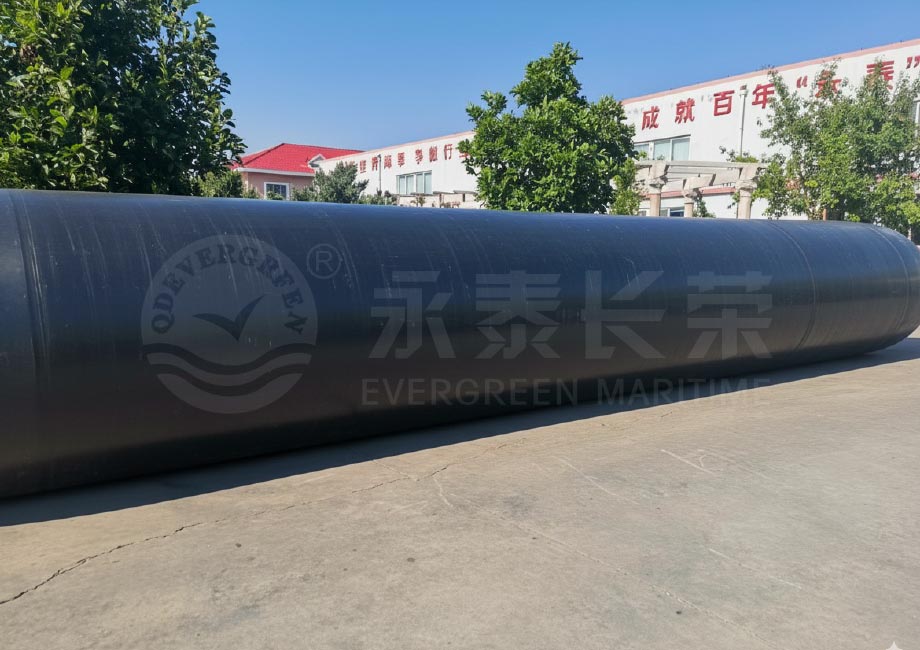

Durable Outer Skin Design

Evergreen ship hauling airbags are constructed with reinforced outer layers to resist damage from sharp marine organisms attached to the hull. For projects requiring extra protection, we can provide airbags with anti-cut steel wire mesh upon request.

Anti-Twisting Design

For airbags longer than 15 meters used in long-distance rolling operations, an anti-twisting design ensures safety and stability throughout the process.

Safe and Hassle-Free Operation

Evergreen ship hauling airbags can remain inflated and functional underwater for up to two weeks without re-inflation, significantly reducing labor intensity and improving efficiency.

Applications

hauling out one 200 tons barge with ship drydocking airbags

Picking up one retired submarine with ship drydocking airbags

3200 T RO-RO cargo ship dry docking with pneumatic rollers

Versatile Use & Capacity

Suitable for both flat-bottom and V-hull vessels, with a proven record of hauling ships weighing up to 7,000 tons. After vessel repairs are completed, ship hauling airbags can also be used to safely launch ships back into the water.

Flexible Deployment

For lighter vessels, natural slipways or simple reinforced ramps are sufficient for hauling operations, making airbags especially useful in remote areas or locations lacking permanent shipyard infrastructure.

Efficiency & Cost Savings

Compared with traditional slipway ship hauling methods, hauling ships with airbags is not restricted by vessel width, offering greater flexibility, faster setup, and significant savings in site construction costs and time.

Usage Guidelines

Even though the outer skin of ship hauling airbags is reinforced, avoid direct contact with marine growth, sharp metal edges, or other abrasive objects under the hull to reduce the risk of damage.

During ship hauling operations, the maximum allowable static lifting pressure can be up to twice the working pressure, but always confirm that this pressure complies with the vessel’s structural strength and bending moment requirements.

Inflate marine airbags slowly, especially the first group positioned under the bow.

After use, wash marine airbags with clean fresh water, dry them completely, and store them properly.

If ship hauling airbags are cut or abraded, perform timely repairs before the next operation.

Advantages of Evergreen Ship Hauling Airbags

Wide Applicability: Works with various vessel types and sizes.

Cost-Effective: Reduces or eliminates the need for permanent slipway construction.

Flexible Deployment: Easily set up in remote or temporary sites.

Environmentally Friendly: Minimal seabed disturbance compared to traditional methods.

Technical Specifications

| Diameter(m) | Maximum Allowed Pressure (MPa) | Maximum Lifting Force at 50% Compressed (Ton/m) |

| 1 | 3.5 | 27.4 |

| 1.5 | 2 | 23.5 |

| 1.8 | 1.8 | 25.4 |

| 2 | 1.5 | 23.5 |

Detailed performance of docking airbags are available on request.

Case Studies

7000 T FLOATING DOCK HAULED TO LAND WITH DRYDOCKING AIRBAGS

7000 T Floating dock hauled to land with drydocking airbags

Light weight 7000 T Floating dock hauled to land with drydocking airbags

How to Choose the Right Ship Hauling Airbag

Our technical team can provide customized calculations and layout plans to ensure safe and efficient hauling operations.

When selecting hauling airbags, consider:

- Vessel type and weight

- Slipway slope and surface conditions

- Operational distance from water to shore

- Frequency of use and storage conditions